How does Craftsman Automation expect to earn ₹900 Cr from data centers?

Synopsis: Craftsman Automation, a diversified engineering manufacturer with operations in India and Europe, is capitalizing on the global data center boom. Strong performance from its aluminium and powertrain segments, coupled with its German subsidiary serving high-value generator orders, positions the company to achieve a USD 100 million revenue target from data centers by 2029-2030. The […] The post How does Craftsman Automation expect to earn ₹900 Cr from data centers? appeared first on Trade Brains.

Synopsis: Craftsman Automation, a diversified engineering manufacturer with operations in India and Europe, is capitalizing on the global data center boom. Strong performance from its aluminium and powertrain segments, coupled with its German subsidiary serving high-value generator orders, positions the company to achieve a USD 100 million revenue target from data centers by 2029-2030.

The global surge in data center demand is reshaping opportunities across the industrial and engineering landscape, and certain niche suppliers are emerging as key beneficiaries. One such company, with a strong manufacturing base spanning India and Europe, is strategically positioned to tap into this specialized market, leveraging decades of engineering expertise and cross-border operational excellence.

About The Company

Craftsman Automation Limited (CAL) was incorporated in 1986 in Coimbatore, Tamil Nadu, by Mr. Srinivasan Ravi. The company operates as a diversified engineering manufacturer, supplying a wide range of components and sub-assemblies on both supply and job-work basis, tailored to customer specifications across the automotive, industrial, and engineering sectors. The shares of the company are trading at Rs. 7,736 with a market capitalization of Rs. 18,454.68 crore. Among institutional investors, the Government of Singapore is a key foreign shareholder, holding a 2.19 percent stake in the company.

Within the automotive segment, CAL manufactures critical powertrain and engine components such as cylinder blocks, cylinder heads, camshafts, and crankcases. These products cater to a broad set of applications, including commercial vehicles, sport utility vehicles, two-wheelers, farm equipment, and earthmoving and construction machinery. The company also operates a non-ferrous sand foundry that primarily serves manufacturers of power transmission equipment.

Beyond automotive, CAL has a strong presence in industrial and engineering segments, offering products such as industrial gears, storage systems, material handling solutions, and locomotive engine components. Its in-house tool room supports injection moulding through the supply of dies and mould bases, while the company also designs and manufactures special-purpose machines used for both metal and non-metal cutting.

With over three decades of operating experience, CAL has developed strong in-house capabilities across the entire manufacturing value chain, including design, process engineering, foundry operations, surface treatment, fabrication, machining, and assembly. The company operates manufacturing facilities with a total built-up area exceeding 3.4 million square feet, strategically located close to key customers to enhance operational efficiency and responsiveness.

As of now, the stock is trading at Rs. 7,380, translating into a market capitalization of Rs. 17,604 crore.

Corporate Structure

Craftsman Automation Limited operates through a well-structured network of domestic and overseas subsidiaries, along with strategic joint ventures, supporting its diversified engineering operations.

The company’s wholly owned subsidiaries include Sunbeam Lightweighting Solutions Private Limited, based in Haryana; DR Axion India Private Limited, located in Tiruvallur; and Craftsman Europe B.V., headquartered in the Netherlands. Through its international operations, CAL also owns Craftsman Germany GmbH, which functions as a holding company in Germany. Under the global entity, Craftsman Fronberg Guss GmbH and Craftsman Fronberg Guss Immobilien GmbH operate as step-down subsidiaries, strengthening the company’s footprint in European casting and manufacturing.

In addition to its subsidiaries, CAL has a joint venture with Carl Stahl through Carl Stahl Craftsman Enterprises Private Limited, based in Coimbatore. This partnership reflects the company’s long-standing collaboration with Carl Stahl, which dates back to the period between 2007 and 2011, during which CAL also established its European subsidiary in the Netherlands.

From a corporate evolution standpoint, the company went public in March 2021, with its equity shares listed on both the BSE and NSE. As part of its growth strategy, CAL acquired a 76 percent stake in DR Axion India Private Limited between 2021 and 2023, followed by the complete acquisition of DR Axion India and Sunbeam Lightweighting Solutions Private Limited during the 2024-2025 period. More recently, the company also completed the acquisition of Craftsman Fronberg Guss GmbH and Craftsman Germany GmbH, further consolidating its presence in the European market.

Business Segments

Powertrain

Craftsman Automation’s powertrain business is diversified across a wide range of products and end-user industries. Its portfolio includes cylinder blocks, cylinder heads, camshafts, transmission components, bearing caps, and turbocharger-related parts, catering to applications across automotive and allied segments. Over the years, the company has played a meaningful role in import substitution by localising the manufacture of several critical powertrain components that were earlier sourced from overseas.

During the first half of FY26, the revenue mix within the powertrain segment was split between Craftsman Automation’s Indian operations, which contributed 85 percent, and Craftsman Germany, which accounted for the remaining 15 percent.

On a quarterly basis, segment revenue rose to Rs. 538 crore in Q2FY26 from Rs. 496 crore in Q1FY26 and Rs. 431 crore in Q2FY25. Operating profitability also improved, with EBIT increasing to Rs. 79 crore in Q2FY26, compared with Rs. 76 crore in the previous quarter and Rs. 64 crore in the same period last year.

The segment is supported by a strong manufacturing footprint, comprising 14 strategically located plants across India and Germany, including two cast iron foundries focused on large-format components. With more than 35 years of experience in machining cylinder blocks and cylinder heads, the company has built deep technical expertise in powertrain manufacturing.

Aluminium Products

The aluminium products segment focuses on highly engineered, lightweight solutions across automotive, industrial, and emerging mobility applications. The product portfolio spans powertrain components such as crankcases, covers, cylinder heads, and transmission housings, as well as structural parts including cradles, intake manifolds, cam covers, and oil filter housings.

In addition, the segment caters to industrial engineering requirements through aluminium castings used in power transmission, locomotives, and oil and gas applications, while also addressing the growing electric vehicle space with components such as battery housings, cooling trays, and motor housings.

Manufacturing capabilities in this segment extend across the entire value chain, covering design and development, toolroom and fixture manufacturing, special-purpose machines, foundry and casting operations, and multiple casting technologies including high-pressure die casting, low-pressure die casting, gravity die casting, and sand casting. These are complemented by precision machining, assembly, surface finishing, and final delivery.

In the first half of FY26, revenue contribution by subsidiaries was distributed across Craftsman Automation at 37 percent, DR Axion at 35 percent, and Sunbeam Lightweighting Solutions at 28 percent. From an industry perspective, four-wheelers accounted for 55 percent of revenues, followed by two-wheelers at 38 percent, with other segments contributing 7 percent.

Quarterly revenues increased sharply to Rs. 1,204 crore in Q2FY26, up from Rs. 1,071 crore in Q1FY26 and Rs. 583 crore in Q2FY25. EBIT for the segment stood at Rs. 141 crore in Q2FY26, compared with Rs. 108 crore in the preceding quarter and Rs. 82 crore in the year-ago period.

Industrial and Engineering Segment

The industrial and engineering segment comprises high-end sub-assemblies, contract manufacturing, and allied activities, supported by integrated facilities capable of delivering end-to-end solutions. Offerings include special-purpose machines, material handling systems, gears and gearboxes, toolroom services, mould bases, and sheet metal components. The segment also has a dedicated focus on storage solutions, covering static racking, shelving systems, vertical storage solutions under the V-store brand, and automated storage and retrieval systems.

In the first half of FY26, storage solutions contributed 63 percent of segment revenues, while other industrial and engineering activities accounted for the remaining 37 percent. Segment revenue increased to Rs. 260 crore in Q2FY26 from Rs. 216 crore in Q1FY26 and Rs. 200 crore in Q2FY25. EBIT for the quarter stood at Rs. 4 crore in Q2FY26, compared with Rs. 5 crore in Q1FY26. This segment operates through four strategically located manufacturing plants across India, including facilities in Coimbatore, Bengaluru, and Pune.

In-House Manufacturing Capabilities

Craftsman Automation has built strong in-house manufacturing capabilities covering the entire product lifecycle, from product and part design supported by simulation to manufacturing process design, tool and fixture development, and the design and manufacture of special-purpose machines. Its operations span aluminium casting through high-pressure, low-pressure, gravity, and sand casting, along with machining, metal forming, heat treatment, gear manufacturing, sheet metal fabrication, powder coating, assembly, and integrated quality assurance and testing.

The company maintains a presence across the full value chain, including product design, prototyping, tool development, manufacturing, assembly, and the production of integrated components. Its manufacturing plants are designed for flexibility, with machinery capable of handling both individual and diversified processes, enabling interchangeable usage to optimise machine productivity, operational efficiency, and time management. Dedicated production lines are configured based on customer order size and frequency, supporting efficient scaling and consistent delivery.

Craftsman Automation operates facilities with a total built-up area exceeding 3.4 million square feet, strategically located to support just-in-time delivery and reduce supply chain risks. During FY26, the company commissioned new projects at its Faridabad Unit-3 and Hosur facilities, strengthening capacity and geographic reach. These plants are designed to insulate customers from localised disruptions, support Tier-2 and Tier-3 export supply to developed markets, and are equipped with state-of-the-art machinery, engineered layouts, robust process controls, and necessary automation to enhance quality and productivity.

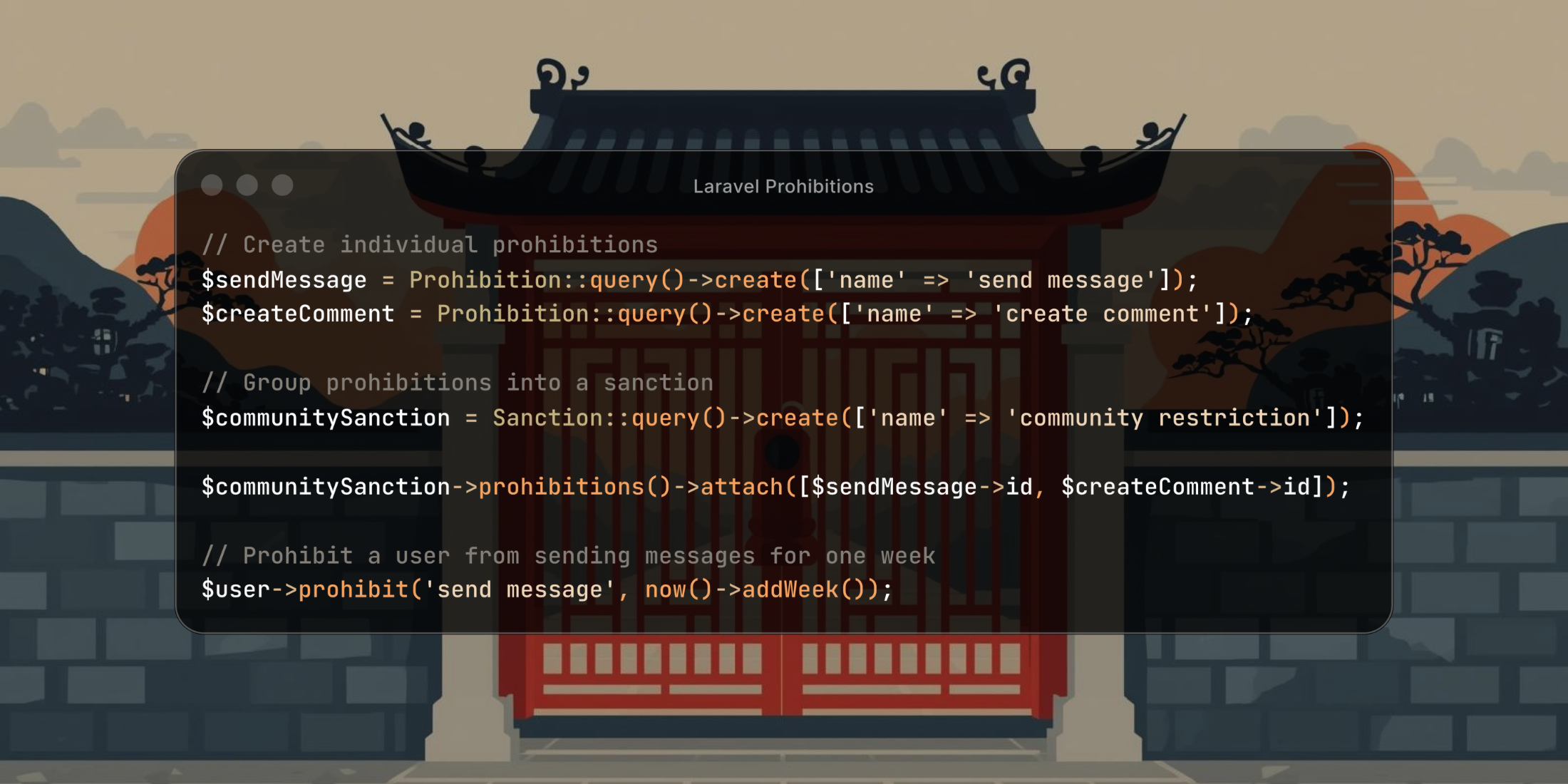

Data Centre Boom As A Tailwind

The surge in global data center demand is proving to be a strong tailwind for the company, particularly through its German subsidiary, Fronberg Guss. The plant is operating at high utilization, generating healthy profitability, and is focused on producing large engines for power generation that are increasingly being used in data centers. The H1 performance reflects this momentum, with revenue of around Rs. 158 crore, EBITDA of Rs. 14.87 crore, EBIT of Rs. 11.4 crore, and PAT of Rs. 8 crore. The order book remains robust, and management expects this growth trend to continue for several years.

Operational Excellence and Quality Confidence

A key differentiator is the company’s operating model. Parts are first validated at Fronberg Guss in Germany before toolings are transferred to India. This approach mitigates quality risks and instills confidence among customers, particularly in the data center segment, where generators are high-cost and extremely sensitive to power fluctuations. Close collaboration between teams in Germany, Spain, and India ensures seamless development and alignment with customer requirements. According to management, “This is giving a lot of confidence to our customers that we will get it first time right because the products are very expensive and the data center customers are also very sensitive for any sort of quality issue.”

Significant Market Opportunity

Data center generators represent a specialized and premium segment, with individual units ranging from one to several million euros depending on size and specifications. The technology and controls for these generators are highly sophisticated, with only a handful of companies globally mastering them. The company is already positioned alongside three of the four major players that command about 70 percent of the market. With more than half of the projected orders already confirmed and the remainder in advanced negotiations, the company is on track to achieve its USD 100 million revenue target from India by 2029-2030, factoring in typical product approval cycles and lead times.

Strategic Growth Without Immediate Capex

Despite the strong order flow and market opportunity, the company does not plan any near-term expansion in Europe. Instead, the focus is on cross-functional development across Germany, Spain, and India to ensure consistent quality, innovation, and efficient transfer of manufacturing capabilities. This strategy not only keeps capex in check but also reinforces its position as a reliable supplier of high-value, quality-sensitive engines for the fast-growing data center industry.

Financial Snapshot – Q2FY26

Quarter-on-Quarter (QOQ): Craftsman Automation’s consolidated sales grew from Rs. 1,784 crore in Q1FY26 to Rs. 2,002 crore in Q2FY26, marking a 12.3 percent increase. Operating profit rose from Rs. 265 crore to Rs. 302 crore, a 14.0 percent growth, while the operating margin remained stable at 15 percent. Profit before tax (PBT) improved from Rs. 94 crore to Rs. 125 crore, up 32.9 percent, and net profit increased from Rs. 70 crore to Rs. 91 crore, representing a 30.0 percent jump over the previous quarter.

Year-on-Year (YOY): Compared with Q2FY25, sales surged from Rs. 1,214 crore to Rs. 2,002 crore, a 64.9 percent increase. Operating profit jumped from Rs. 193 crore to Rs. 302 crore, up 56.5 percent, while operating margin moderated slightly from 16 percent to 15 percent. PBT rose from Rs. 82 crore to Rs. 125 crore, marking a 52.4 percent increase, and net profit grew from Rs. 62 crore to Rs. 91 crore, an increase of 46.8 percent.

The segmental revenue mix for H1FY26 shows aluminium products contributing 60 percent, powertrain 27 percent, and industrial and engineering 13 percent, reflecting the company’s strong focus on high-value aluminium solutions.

Disclaimer: The views and investment tips expressed by investment experts/broking houses/rating agencies on tradebrains.in are their own, and not that of the website or its management. Investing in equities poses a risk of financial losses. Investors must therefore exercise due caution while investing or trading in stocks. Trade Brains Technologies Private Limited or the author are not liable for any losses caused as a result of the decision based on this article. Please consult your investment advisor before investing.

The post How does Craftsman Automation expect to earn ₹900 Cr from data centers? appeared first on Trade Brains.

What's Your Reaction?